As the world increasingly turns to hydrogen as a clean energy carrier, companies are exploring which electrolyzer technology is the right choice to achieve their production goals. Recently, pressurized alkaline electrolyzers have emerged as a key point of discussion and research in this selection process—and for good reason.

If you're new to evaluating alkaline technology or to pressurized alkaline in particular, we'll walk you through the impact of pressurization, as well as the technical and financial advantages of pressurized alkaline over atmospheric alkaline electrolyzers.

A primer: Why is pressurized output so important?

Most (if not all) of the applications that use hydrogen need an input pressure higher than atmospheric pressure of 1 bar. Typically, pressure needs per end-use fall into these ranges:

Historically, most alkaline technology has been atmospheric, which means that a compressor was always required in addition to the electrolyzer system itself. However, compressing hydrogen comes with some challenges, mostly due to the physical properties of hydrogen. As the first element in the periodic table, hydrogen is also the lightest, which means that its compression requires a lot of energy. For instance, compressing hydrogen to 700 bars would require 18 megajoules of energy.* This would mean that, if stored at 700 bars, about 15% of the energy contained in the hydrogen is spent compressing it!**

Now, as an alternative to systems with both atmospheric electrolyzers and compressors, pressurized systems have entered the market. These offer significant advantages, as they can produce pressurized hydrogen output without requiring a separate compressor in the system. Most pressurized electrolyzers systems available today are found in pressure ranges of between 10 and up to 40 bars, which meet most needs. Although pressurized electrolyzers with output of up to 70 bars are foreseen in the long term, these are not expected any time soon, as these higher pressures are only required for some specific applications—like transportation, mobility, or storage. Regardless, even in these instances, there are still advantages to using a pressurized alkaline electrolyzer, because they offer greater efficiency gains when you're starting any secondary compression from 15 bars rather than from atmospheric pressure.

So as you can see, the baseline advantage of pressurized hydrogen is its cost efficiency for compression, but there's more to it than that.

The key advantages of pressurized over atmospheric electrolyzers

Let's take a closer look at the advantages of a pressurized electrolyzer system versus an atmospheric electrolyzer system, specifically when it comes to energy consumption, capex requirements, plant efficiencies, and load flexibility.

1. Reduced energy consumption

As we know, hydrogen is a light molecule, and compressing it consumes more energy per kilogram of gas than any other gas. We also know that the energy required to compress it is not proportional to the finished pressure, meaning that the first few bars of compression are the most energy intensive.

At the system level, that means there are significant advantages to using pressurized electrolyzers, as they eliminate the bulky and energy-intensive first stages of compression between atmospheric pressure and a few bars. The table below shows the energy required for compression to 90 bars when starting at 1 bar for an atmospheric electrolyzer versus 15 bars for pressurized electrolyzer.

Using a 15-bar pressurized alkaline electrolyzer instead of an atmospheric one saves 60% in energy consumption when compressing hydrogen to 90 bars; when we tally this up later in the article, you'll see that these savings are quite substantial.

Depending on the required final pressure, it's possible that a compressor may still be needed, but it would still be more cost-effective and energy-efficient—lowering electricity requirements—to start compression from a few bars rather than atmospheric pressure.

2. Reduced capex

Perhaps the largest cost advantage of pressurized alkaline is the capex savings it offers by eliminating the need for a separate compressor. Using an atmospheric electrolyzer that requires an additional compressor would result in a 70% increase in the initial capex for a compressor to compress to 90 bars compared to a pressurized electrolyzer beginning at 15 bars.

3. Increased plant-level efficiencies due to reduced operational costs, footprint, and maintenance

Not only does purchasing a compressor increase your capex, but that compressor also adds a proportionally equal cost to your operating expenses***—costs that would be eliminated when using a pressurized system.

Without a compressor, we can also take up a smaller footprint. The pressurized system itself is also smaller; it produces more hydrogen gas per unit volume of electrolyte, so it can achieve the same production rates as an atmospheric system in a smaller space. In the end, that total smaller footprint equates to lower construction and infrastructure costs.

Lastly, removing the compressor reduces the complexity and maintenance requirements for the system itself due to simplified integration. It also helps increase safety, and potential issues or failures can be minimized during both the system build and operation. Overall, your reliability and performance can be enhanced when there are few connections or interfacing between systems.

4. Supported load flexibility for renewable resources

Pressurized alkaline electrolyzers also offer major operational gains because they offer substantial flexibility when it comes to capacity variation requests or intermittent energy loads from renewable energy sources such as solar, wind, and hydroelectric. Compared to atmospheric systems, pressurized ones can follow renewable load far more easily due to an increased ramp-up/-down rate. For example, John Cockerill Hydrogen pressurized alkaline systems have a ramp-up rate of 4%/second, compared to ~10%/minute on average for atmospheric alkaline electrolyzers. This translates to a +2,000% increased performance for pressurized systems. And as pressurized systems offer shorter response times, they're better equipped to respond to changes in power input, allowing them to compete with other technologies such as proton exchange membrane (PEM) when combined with renewable energy.

Put it into practice: What do you gain by choosing pressurized alkaline?

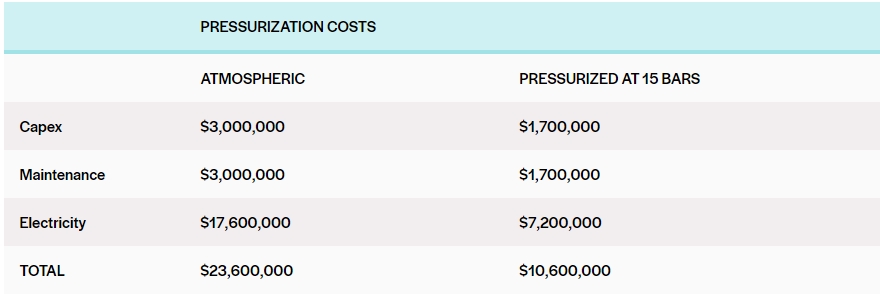

Imagine a 100-MW project (20,000 Nm3/h) with an electricity price at $25/MWh. The lifetime of the project is 20 years with 8,000 hours of operation per year. The required output pressure is 90 bars.

If you have an atmospheric electrolyzer, you will need to pay $1.3 million in additional capex for a compressor at the beginning of the project.

Maintenance adds up to another $1.3 million to be spent over the lifetime of the project. Electricity costs for compression up to 90 bars will be $17.6M, which is $10.4M more than using a pressurized 15-bars electrolyzer. Your total additional costs to run an atmospheric electrolyzer instead of a pressurized one comes to $13 million.

Keep in mind that these costs don't even consider plant downtime because of maintenance or reduced availability due to the compressor system! Altogether, this equates to an decrease of roughly $130/kW on your plant simply by choosing a pressurized electrolyzer instead of an atmospheric one.

Pressurized alkaline is more advantageous across the board

For electrolyzer technology, the advantages of pressurized systems such as John Cockerill Hydrogen's 15-bar technology compared to atmospheric alkaline stacks are increasingly apparent, offering benefits like improved plant efficiency, reduced energy consumption and capex, as well as load flexibility.

Furthermore, the flexible operation, ability to integrate with renewable energy sources, and historical robustness of alkaline systems make them ideal for scaling up hydrogen production in industrial applications that are using renewables. Through the widespread adoption of pressurized alkaline technology, we can expect to see a significant step forward in advancing the deployment of large-scale clean hydrogen production processes.

*Eberle, U, Felderhoff, M and Schuth, F, Chemical and Physical Solutions for Hydrogen Storage. Angewandte Chemie-International Edition, 2009. 48(36): p6608-6630.

**https://www.thechemicalengineer.com/features/the-unbearable-lightness-of-hydrogen/

***Maintenance of compressors is estimated to be 5% of initial Capex per year