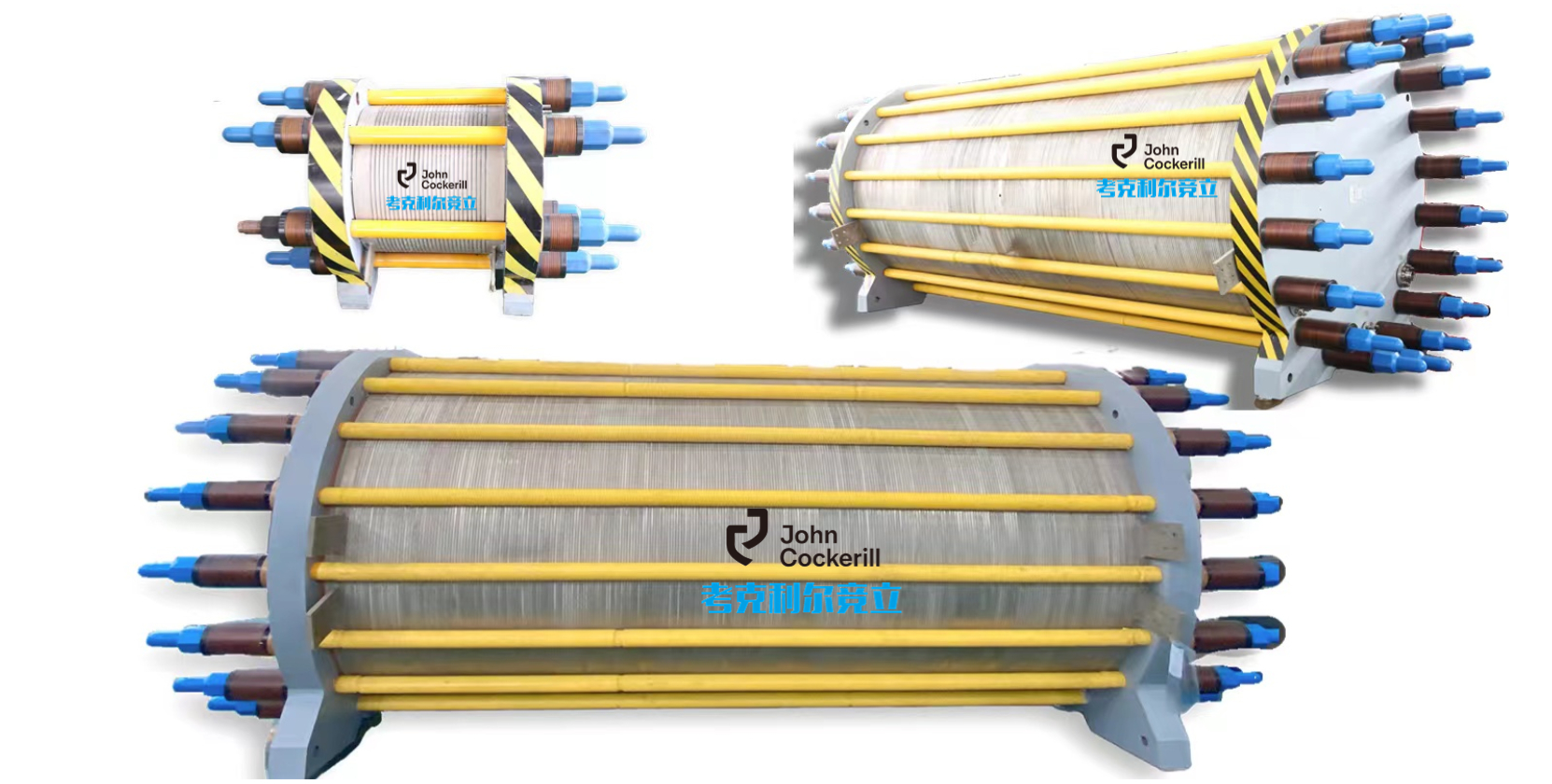

1. Main equipment composition: electrolytic cell auxiliary equipment frame.

2.The parts of the main equipment: electrolyzer,auxiliary equipments frame.

3.The parts of the auxiliary equipment: water supply tank, lye tank and water supply pump.

4.The parts of the electric control equipment:rectifier cabinet, control cabinet,distribution cabinet and transformer.

5.The type of electrolyzer :Pressed filter bi-polar filter.

6. Features:compact construction,operation convenient,advanced design, performance reliability,ultra pure gas,adjustable output,on-off free, lower power consumption,easy installation,advanced control, simple maintenance,longer life,easy operation, no pollution. Among them, the electrolytic cell, auxiliary frame and purification frame of 2-30m3/h hydrogen production equipment can be integrated design;

7. Widely used: electric power, electronics, metallurgy, building materials, chemical, meteorology, aerospace and new energy, etc.